- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

Liquid ring vacuum pump

Home>PRODUCTS>Vacuum pump>Liquid ring vacuum pump

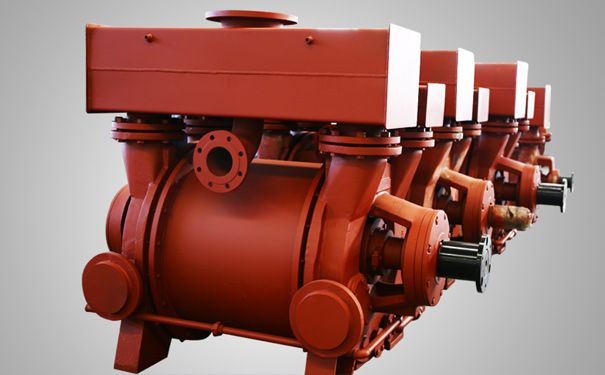

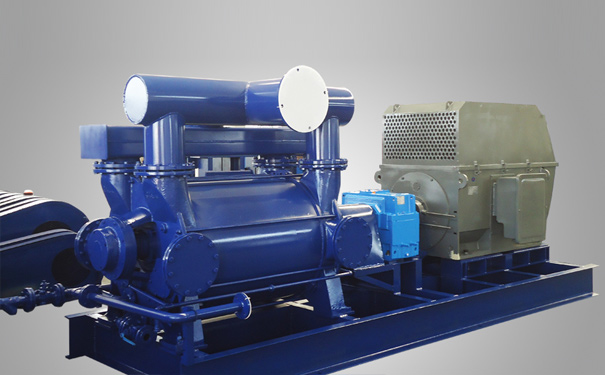

2BE3 Liquid ring vacuum pump and compressor

Detailed Introduction

■ Features:

l This series of pumps are with single-stage single-action structures, having the advantages of simple structure, easy maintenance, reliable operation, energy efficient and being suitable for harsh conditions with large water discharge and overloaded shock wave.

l The impeller is made by welding and high temperature solution treatment. The blade is stamped and formed in one time and with reasonable profile. The hub is processed by high precise lathe and tested by dynamic balancer. The impeller and shaft are matched by hot fitting to achieve reliable performance and stable operation. It is suitable to work in harsh conditions with overloaded shock wave.

l It carries with air water separator, inlets & outlets in multi positions. There is maintenance access to the exhaust valve on the pump cover. The space between the impeller and baffle plate are adjusted by the gland at both ends of the shaft. All our pumps are tested by the quality control center and of superior and reliable performance.

■2BE3 liquid ring vacuum pump profile

2BE3 series water-ring vacuum pump and compressor are high-efficiency energy-saving products developed by our company based on many years of scientific research and production experience and combined with advanced technology of similar products in the world. they are usually used to pump gas that does not contain solid particles, is insoluble in water and is non-corrosive, so as to form vacuum and pressure in closed containers. Liquid ring vacuum pump can also be used to pump corrosive gas or use corrosive liquid as working fluid by changing structural materials and adding anti-corrosive coating. It is very suitable for long-term and continuous operation.

■ The supplying range of pumps can be flexibly chosen according to customers’ requirements.

Pump head: including the upper-type separator, connecting pipe.

Whole set of the machine: including the pump head, the upper-type separator, connecting pipe, motor, base, hood, pump and motor connector or pump pulley, belt.

Vacuum pump unit: including vacuum pump machine, gas-water separator, check valve, bellows and connected piping, electrical contact vacuum gauge, auto-decompression starting cabinet.

Complete sets of equipment: including the whole set of vacuum pump machine, gas-water separator (with level gauge), heat exchangers, valves, normally closed valves, filters, vacuum gauge, pressure gauge, pipe, electric control cabinet.

Inlet pressure below 33 mbar (absolute), 2 stages or multi-stages vacuum system (water ring - Roots unit) will be in use.

● Varied transmission methods, such as: coupler drive, pulley drive, reducer drive.

● Stainless steel materials (304, 316L) or special ones can be provided according to the corrosion of media; Packing seals and mechanical seals or others can be provided on request.

■ Applications:

2BE3 series are widely used in paper making, chemical, petroleum, light industry, pharmaceutical, food, building material, electrical appliances, coal washing, mining selection, fertilizer, etc. industries. It running reliability is universally praised. In coal industry, it can be used to pump and exhaust highly flammable and explosive gases, like gas, methane; gas draining station equipped with movable system can be designed and installed on the ground.

Technical Parameter

Model No. | Minimum suction pressure(mbar) | Speed(r/min) | Max. Suction Capacity(m³/min) | Max. shaft power(kw) | Motor power(kw) | Weight of the pump head (connecting pipe and separator) |

| 2BE3400 | 160 | 340 | 80 | 80 | 90 | 2950 (3420) |

| 390 | 94 | 95 | 110 | |||

| 440 | 105 | 114 | 132 | |||

| 490 | 115 | 130 | 160 | |||

| 530 | 125 | 150 | 185 | |||

| 570 | 133 | 166 | 185 | |||

| 610 | 143 | 190 | 220 | |||

| 2BE3420 | 160 | 340 | 118 | 110 | 132 | 3400 (3940) |

| 390 | 131 | 130 | 160 | |||

| 440 | 146 | 150 | 185 | |||

| 490 | 160 | 177 | 200 | |||

| 530 | 170 | 193 | 220 | |||

| 570 | 183 | 220 | 250 | |||

| 610 | 192 | 260 | 315 | |||

| 2BE3500 | 160 | 260 | 146 | 138 | 160 | 5500 (6260) |

| 300 | 170 | 173 | 200 | |||

| 340 | 191 | 187 | 220 | |||

| 380 | 210 | 238 | 280 | |||

| 420 | 230 | 275 | 315 | |||

| 470 | 260 | 338 | 400 | |||

| 2BE3520 | 160 | 260 | 178 | 175 | 200 | 6100 (6900) |

| 300 | 205 | 210 | 250 | |||

| 340 | 233 | 248 | 280 | |||

| 380 | 257 | 287 | 315 | |||

| 420 | 281 | 333 | 400 | |||

| 470 | 315 | 410 | 450 | |||

| 2BE3600 | 160 | 230 | 213 | 208 | 250 | 8380 (9380) |

| 260 | 243 | 245 | 280 | |||

| 290 | 267 | 280 | 315 | |||

| 320 | 292 | 328 | 355 | |||

| 350 | 317 | 370 | 400 | |||

| 400 | 360 | 472 | 500 | |||

| 2BE3620 | 160 | 230 | 260 | 248 | 280 | 9270 (10370) |

| 260 | 293 | 297 | 355 | |||

| 290 | 326 | 340 | 400 | |||

| 320 | 366 | 385 | 450 | |||

| 350 | 386 | 445 | 500 | |||

| 400 | 438 | 570 | 630 | |||

| 2BE3670 | 160 | 210 | 302 | 285 | 315 | 11700 (13010) |

| 240 | 348 | 348 | 400 | |||

| 270 | 386 | 412 | 450 | |||

| 300 | 426 | 475 | 560 | |||

| 320 | 450 | 515 | 560 | |||

| 330 | 465 | 540 | 630 | |||

| 370 | 518 | 660 | 710 | |||

| 2BE3720 | 160 | 190 | 366 | 340 | 400 | 14290 (15840) |

| 210 | 410 | 390 | 450 | |||

| 240 | 460 | 465 | 560 | |||

| 270 | 510 | 550 | 630 | |||

| 300 | 565 | 640 | 710 | |||

| 340 | 633 | 800 | 900 |

*The data marked by * is suitable for special processing.