- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

Semi-automatic Type

Home>PRODUCTS>Round Bar Peeling Machine>Semi-automatic Type

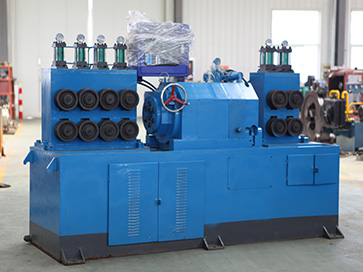

WXC40C

Product introduction: WXC Series Centerless Lathe(commonly known as peeling machine)is a new generation high-efficiency lathe machine which is specialize...

Detailed Introduction

WXC Series Centerless Lathe(commonly known as peeling machine)is a new generation high-efficiency lathe machine which is specialized in processing of metal bar surface such as slender shaft. It can not only quickly remove defects on the surface of round steel such as decarburization layer and cracks, but also realize relatively high precision and roughness. It is especially suitable for processing of super long round steel bar, with working efficiency several times of the traditional processing technology.

This machine is mainly applied in the production of bright material and bright steel bar, and in the field of machinery manufacturing, auto parts, bearing production, spring manufacturing, military enterprises, the production and processing of slender shaft, titanium bar, copper bar, aluminum bar, magnesium bar and other non-ferrous metal bar or tube, and in the field of other machinery equipment manufacturing for material preparation.

WXC series of centerless lathe includes CNC type and semi - automatic type.

Semi automatic type is operated both hydraulically and manually. For example, tool is adjusted manually, feeding and extracting are realized with hydraulic controlled clamping device, and auto material loading and unloading are finished with pneumatic and electric controlled device. Operated with ease, high in cost performance, this machine is quite suitable for small or medium enterprises which requires lower degree of automation.

This machine is mainly applied in the production of bright material and bright steel bar, and in the field of machinery manufacturing, auto parts, bearing production, spring manufacturing, military enterprises, the production and processing of slender shaft, titanium bar, copper bar, aluminum bar, magnesium bar and other non-ferrous metal bar or tube, and in the field of other machinery equipment manufacturing for material preparation.

WXC series of centerless lathe includes CNC type and semi - automatic type.

Semi automatic type is operated both hydraulically and manually. For example, tool is adjusted manually, feeding and extracting are realized with hydraulic controlled clamping device, and auto material loading and unloading are finished with pneumatic and electric controlled device. Operated with ease, high in cost performance, this machine is quite suitable for small or medium enterprises which requires lower degree of automation.

Technical Parameter

| model | WXC40C | |

|---|---|---|

| material requirement | diameter range (mm) | 11<dia<40 |

| material length (mm) | ≥1400 | |

| yield strength(Mpa) | ≤1100 | |

| surface hardness | ≤HB320 | |

| straightness (mm/m) | ≤1.5 | |

| diameter tolerance | according to GB 702-2004 second group | |

| roundness(mm) | ≤50% of diameter tolerance | |

| surface roughness(Ra) | ≤25~50μm | |

| finished product | diameter range(mm) | 10≤dia≤39 |

| diameter cutting depth(mm) | 0.5~2.0 | |

| diameter tolerance | ≤h10 | |

| surface roughness (Ra) | ≤6.3μm | |

| feeding speed (m/min) | 1.0~10.0 | |

| cutting head rotation rate per minute(rpm) | 900~2400 | |

| main motor(kw) | 45 | |

| total capacity(kw) | 65 | |

| compressed air (prepared by user) | 0.5~0.8MPa,1.8m3/min,0.8 m3 up air tank with two stage oil water separator and compressed air freezing type drying machine | |