- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

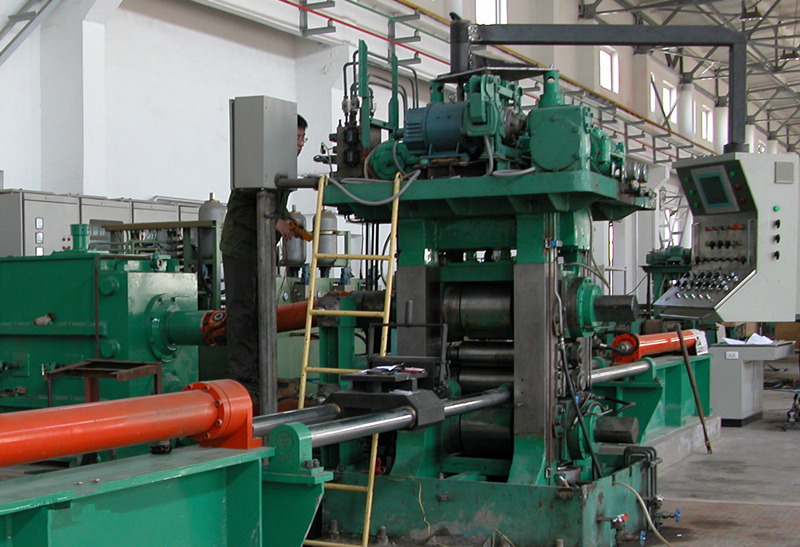

Tube Rolling Mill

Home>PRODUCTS>Rolling Mill>Tube Rolling Mill

Cold Tube Milling Machine

Product introduction: The main structure of LG cold tube rolling mill is composed of machine bed, rotary feeding mechanism, frame, a main motor, core rod...

Detailed Introduction

The main structure of LG cold tube rolling mill is composed of machine bed, rotary feeding mechanism, frame, a main motor, core rod, transmission system, electrical system, etc. With the development of technology, nowadays the rotary feeding mechanism has been evolved into single rotation, double feeding, double rotation, single feeding in,and double rotation double feeding in. And the usual feeding mode can be divided into mechanical feeding, photoelectric feeding, and servo feeding. The most critical part of one cold rolling mill is the frame, which includes roller, gear, rack, etc.. The working principle can be described as follows. By creating regular cavity by roller and mandrel, steel tube can be rolling milled taking advantage of elastic deformation of metal. The cold tube rolling mill machine can achieve cold rolling process to the shell using ring hole with relatively good first time rolling performance, and can process nonferrous metal seamless pipe of normal precision as well.

The most obvious characteristic of cold mill is the high material utilization, with better precision and surface roughness than cold tube drawing machine.

The most obvious characteristic of cold mill is the high material utilization, with better precision and surface roughness than cold tube drawing machine.

Technical Parameter

| LG90-H Single line long stroke cold tube milling machine | ||||

|---|---|---|---|---|

| NO. | ITEM | PARAMETER | UNIT | |

| 1 | material tube | outer diameter | Ф76~Ф142 | mm |

| tube thickness | 3~15 | mm | ||

| length | ≤6000 | mm | ||

| 2 | finished tube | outer diameter | Ф45~Ф114 | mm |

| tube thickness | 2~12 | mm | ||

| 3 | Rack travel length | 1003.4 | mm | |

| 4 | Rack travel times | 65~85 | times/min | |

| 5 | Turning angle | 31°~26°(Double rotation) | ||

| 6 | feeding rate | 2~12(single feeding in) | mm | |

| 7 | feeding mode | Side way feeding and non continuous feeding | mm | |

| 8 | Roller diameter | Ф450×Ф180×Ф250 | mm | |

| 9 | main motor | capacity | 200 | kw |

| RPM | 1000 | rpm | ||

| 10 | size | length×width×height | 2800×5150×2370 | mm |