- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

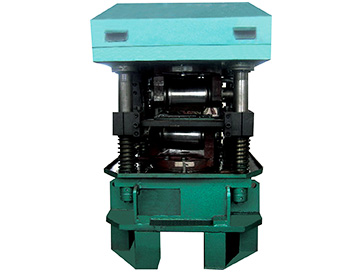

2 Beam 4 Column Type

Home>PRODUCTS>Straightening Machine>Round Steel Two-roller Straightening Machine>2 Beam 4 Column Type

JY20

Product introduction: JY Series of straightening machine can realized precise straightening and polishing on the after peeling or grinding metal bar surf...

Detailed Introduction

JY Series of straightening machine can realized precise straightening and polishing on the after peeling or grinding metal bar surface utilizing the special curves and angles between the top and bottom two rollers. It can be used in black bar material straightening as well.

There are 3 types of structure in straightening machine, two beam four column structure, prestressed structure and frame structure.

The straightness can be up to 0.15——0.4mm/m , and the roughness Ra<1μm after straightening.

The comparison for the three structures:

Stability: frame structure>prestressed structure>two beam four column structure

Precision: frame structure>prestressed structure>two beam four column structure

Speed: frame structure>prestressed structure>two beam four column structure

Main technical character:

1.The concave and convex roller linear contact straightening can realize full length processing with high precision.

2.Constant pressure load control and roller compaction principle and flexible frame structure are applied to make it more suitable for high strength materials straightening. With larger straightening force and better security, it can both protect the machine and at the same time reduce the phenomenon of diameter shrinkage of bar ends.

3.With separate hydraulic system, pressure holding and load releasing can be convenient, fast, secure and reliable.

4.Better cost performance with low price and high quality compared with similar products.

5.The guide plate adopts gantry structure, which means convenient, fast, and reliable installation.

6.Overall framework of the structure means the strength of the whole machine is high, and the position of the roll gap is accurate.

7.Frequency converter adds brake unit and braking resistor, which increases the durability of the converter.

There are 3 types of structure in straightening machine, two beam four column structure, prestressed structure and frame structure.

The straightness can be up to 0.15——0.4mm/m , and the roughness Ra<1μm after straightening.

The comparison for the three structures:

Stability: frame structure>prestressed structure>two beam four column structure

Precision: frame structure>prestressed structure>two beam four column structure

Speed: frame structure>prestressed structure>two beam four column structure

Main technical character:

1.The concave and convex roller linear contact straightening can realize full length processing with high precision.

2.Constant pressure load control and roller compaction principle and flexible frame structure are applied to make it more suitable for high strength materials straightening. With larger straightening force and better security, it can both protect the machine and at the same time reduce the phenomenon of diameter shrinkage of bar ends.

3.With separate hydraulic system, pressure holding and load releasing can be convenient, fast, secure and reliable.

4.Better cost performance with low price and high quality compared with similar products.

5.The guide plate adopts gantry structure, which means convenient, fast, and reliable installation.

6.Overall framework of the structure means the strength of the whole machine is high, and the position of the roll gap is accurate.

7.Frequency converter adds brake unit and braking resistor, which increases the durability of the converter.

Technical Parameter

| JY20 | |||

|---|---|---|---|

| material requirements | diameter range(mm) | Φ6≤d≤Φ20 | |

| length(mm) | ≥2000 | ||

| surface hardness | ≤HB320 | ||

| yeild strength(Mpa) | σb≤1000 | ||

| straightness(mm/m) | ≤3.0 | ||

| diameter tolerance | ≤h10 | ||

| roundness | ≤50% of diameter tolerance | ||

| surface roughness(Ra) | ≤6.3μm | ||

| after straightening | straightness(mm/m) | ≤0.25 | |

| surface roughness(Ra) | ≤0.8μm | ||

| diameter tolerance | ≤h9 | ||

| number of roller(pcs) | 2 | ||

| roller diameter(mm) | Φ180 | ||

| feeding speed(m/min) | 2~15 | ||

| main motor(kw) | 7.5kw X 2 | ||

| Lifting motor(kw) | 1.1 | ||

| total capacity(kw) | 18 | ||