- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

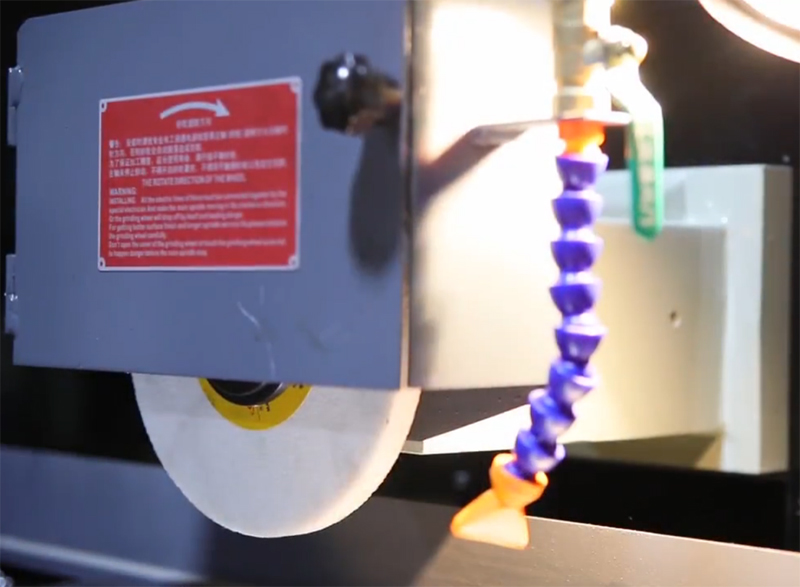

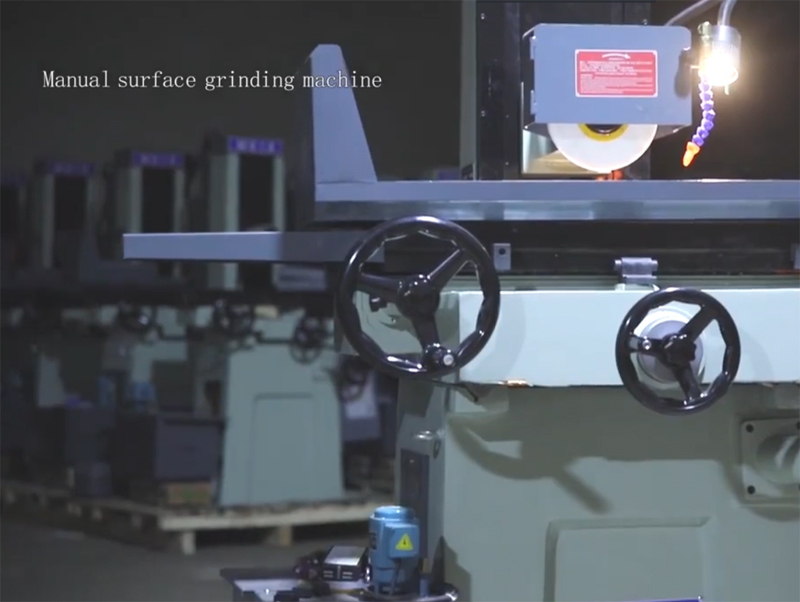

M3070 Hydraulic Surface Grinding Machine

Detailed Introduction

Technical Introduction:

The hydraulic system of M3070 hydraulic surface grinding machine is composed of a set of quantitative motor pumps. The maximum flow of the pump is 18L/min, the motor power is 1.5kw, the working pressure of the pump can reach 3Mpa, and the pressure of the system is regulated by the overflow valve.The main mechanical valve for grinding machine valve, divided into two parts, mechanical reversing control, throttle speed control.Throttling speed regulation part has unloading function, can realize the start and stop of the work table.The valve also has buffer adjustment function.The machine has the characteristics of easy operation, flexible and reliable, no vibration, stable precision, good thermal stability, low noise and easy maintenance.

What is surface grinder?

The surface grinding machine is a machine tool used to provide precision ground surfaces, either to a critical size or for the surface finish. It can process the work pieces with either the peripheral side or vertical plane of the grinding wheel. Usually There are three basic types of surface grinders: horizontal-spindle, vertical-spindle, single disc grinders and double-disc grinders. We only provide horizontal spindle type surface grinder.

How does a surface grinder work?

The work pieces are held in place by a magnetic chuck which directly fixed to the work table or held by other clamps. The work table makes longitudinal movement driven by hydraulic power and the grinding head can move transversely on the drag plate, hydraulically and or manually driven is available. Drag plate together with the grinding head can move vertically along the column, driven manually or mechanically.

The machine can grind work pieces made of steel, cast iron and non-ferrous metal etc.

Note: above pictures are for reference only, the machine will be subject to the actual equipment.Please check the Tab Technical Parameter for detail specification.

Feel free to contact: haige@haigechina.com for further inquiry.

Technical Parameter

Techniques and Procedures | ||

Tabie face dimensions | LxW(mm) | 700x300 |

Lonitudinal travel | mm | 720 |

Table cross travel | mm | 340 |

Grinding head vertical movement distance | mm | 500 |

Accuracy of vertical feed hand wheel | mm | 0.01mm/Grid 2mm/Circle |

Precision infeed handwheel | mm | 0.02mm/Grid 4mm/Circle |

Table T-slot | mm | 14x1 |

Grinding spindle speed | r/min | 1450 |

Grinding motor power | kw | 4 |

Cooling pump motor power | kw | 0.04 |

Frequency | Hz | 50 |

Wheel size | mm | 350x25x75 |

Net weiiiight | kg | 1500 |

Overall dimensions of machine | LxWxH | 1.80x1.65x1.90 |