- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

Coil To Coil

Home>PRODUCTS>Production Line>Coil To Coil

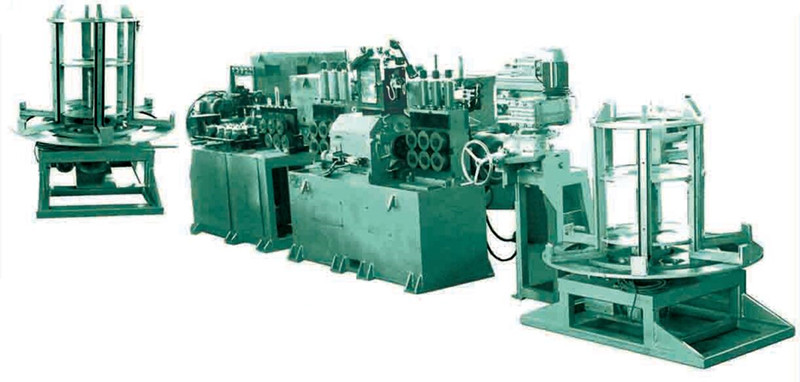

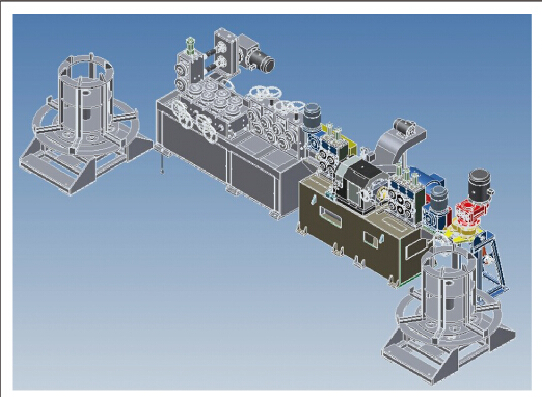

Coil to coil production line

Detailed Introduction

1.Introduction of the production line

Coil to coil production line is a serial of the machines includes payoff & straightening machine, peeling machine, clamping mechanism, pre-bending device, recoiler machine etc. through above machines, the black coil rod will be processed to bright coil rod with good surface quality. We provide 3 different specification:

Diameter of the wire from 5-16mm, 12-25mm, 15-30mm.

2.Take an example of coil to be processed with diameter 6mm to 25mm:

14 pay-off / uncoiler(Φ6-14mm)→14 Horizontal&vertical straightening machine(Φ6-14mm)→25 uncoiler & straightener all-in-one machine(Φ14-25mm)→WXC30S peeler(Φ6-25mm)→hydraulic clamp mechanism(Φ6-25mm)→25 pre-bending device(Φ6-25mm)→25 recoiler(Φ6-25mm)

Description:(1)for material with diameter of 6mm - 14 mm: Lift the coil into the pay off device with crane, Manually pull coil straight into 14 horizontal & vertical straightening machine, after straightening, the wire rod will go through the center line of the 25 uncoiler & straightener all-in-one machine which the straightening rolls have been open widely, (it means this machine doesn’t run, the wire just pass through the machine without any processing), then the wire go into WXC30S CNC peeling machine,after peeling, go into 25 pre-bending machine through clamping device, and then enter the 25 recoiler in coil.

(2)For material with diameter of 14mm-25mm: the coil is placed on the storage cross arm of the 25 uncoiling & straightening machine. After automatic feeding, vertical straightening and horizontal straightening, it enters the WXC30S CNC peeling machine. After peeling, it is sent into the 25 pre-bending machine through the clamping mechanism, and then enters the 25 recoiler machine in coil.

More information, please feel free send us your inquiry.

Technical Parameter

Uncoiler part:

Parameters of Uncoiler & pre straightener all-in-one machine | ||

uncoiler | OD of coil | 1500mm |

ID of coil | 800mm | |

Height of coil | 1000mm | |

Weight of coil | ≤2T | |

motor(point straightener and uncoiler share one motor, Driven by chains and sprockets) | 7.5kw | |

Feed mode | mechanical | |

hardness | <HB320 | |

Point straightener | Quantity/diameter/material of press rolls | 4pcs / φ280mm / Cr12 |

Adjustment of roll | hydraulics | |

Vertical&horizontal straightener | Diameter of wire | Φ14mm – φ22mm |

Quantity/diameter/material of vertical straightener rolls | 7pcs/ φ280mm / Cr12 | |

Quantity/diameter/material of horizontal straightener rolls | 7pcs/ φ280mm / Cr12 | |

motors for controlling the 4 rolls of vertical straightener | 11kw | |

Feed speed | 3-15m/min | |

Center line height | 950mm | |

Peeling part:

model | WXC30S | |

Input material | Process range(mm) | Φ6~Φ22X2000~unlimited |

Tensile strengthσb(Mpa) | ≤1000 | |

Hardness of surface | ≤HB320 | |

straightness(mm/m) | ≤1. 5 ① | |

Dia tolerance | GB 702-88,grade 2 | |

roundness | ≤50% of dia tolerance | |

Surface roughness(Ra) | ≤25~50mm | |

Output material | Dia range(mm) | Φ5.5~Φ21 |

Unilateral cutting depth(mm) | 0.20~0.75(Max:1mm) | |

Dia tolerance | · ≤h10 (standard tolerance grade) | |

Surface roughness(Ra) | ≤3.2-6.3μm | |

roundness(mm) | ≤0.04 | |

Cutting speed(CVT, m/min) | 2.0~12.0(speed need to be reduced when processing with Continuous chip, high strength, high hardness, large cutting depth, large and small diameter materials and special materials) | |

Rotation speed(CVT)(r/min) | 450~1250 | |

Main motor power(kW) | 45 | |

Feed motor power(kW) | 4(pinch in)+4(extract out) | |

Total dimension(m)(for reference) | Main machine 2.5X2.2X1.5 | |

Total installed power with chip conveyor(kw) for your reference | 60 | |

Compressed air (user prepare) | 0.5~0.8MPa、1.8m3/min、0.8 m3 , gas storage tank, with two stage oil and water separator and compressed air refrigerated dryer | |