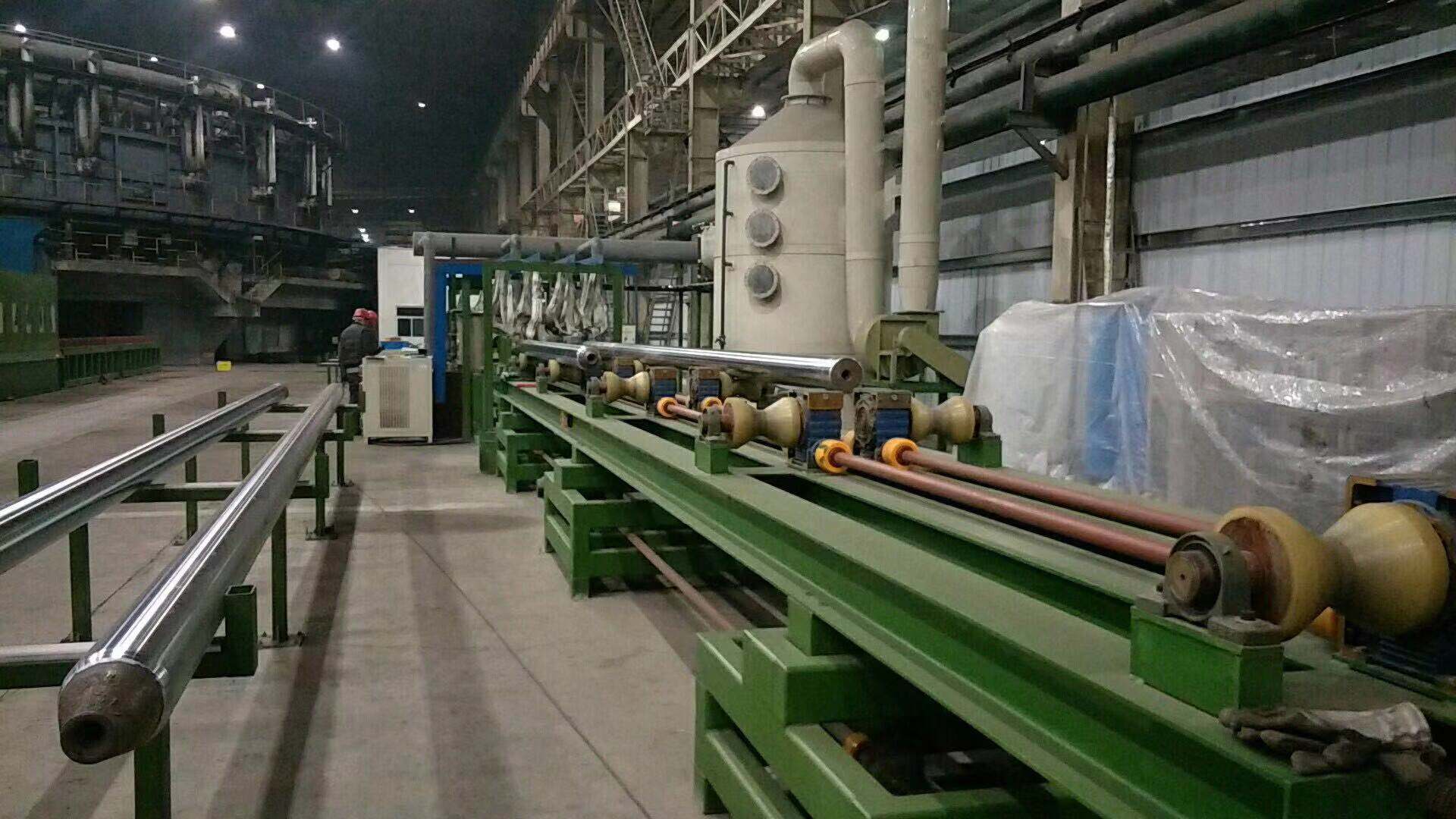

The equipment is used for continuous hard chromium plating on the outer surface of MPM mandrel (round bar), simultaneous electroplating of 2 pieces.

Composition of Equipment

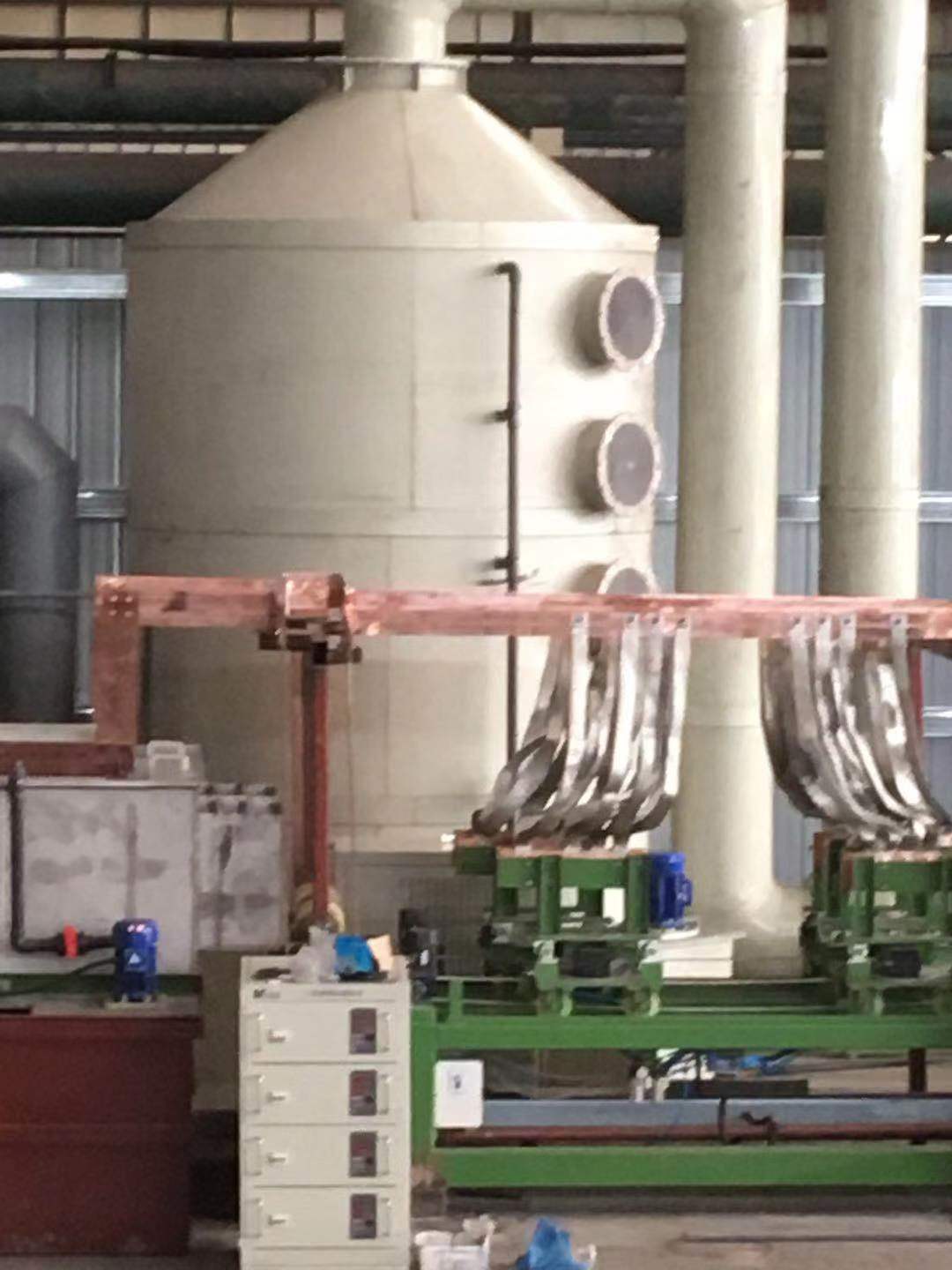

It mainly consists of motor-driven adjustable lifting system (input table roller&output table roller), polishing activation system before and after plating, ultrasonic degreasing system before plating, reverse electro-etching(anodic treatment), electroplating system, conductive system, ventilation system, automatic temperature control system, electrical control system, loading racks and unloading racks, filter for plating solution, freezer for plating solution, etc.

Work Process

manually scrubbling → Input table roller → workpiece connection → conductive clip(front) → wet polishing activation before plating → ultrasonic degreasing(oil removal) → reverse electro-etching(anodic treatment) → electroplating → conductive clip (back) → wet polishing activation after plating → individual bracket → dehydrogenation furnace → Output table roller → disassemble the connection