- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

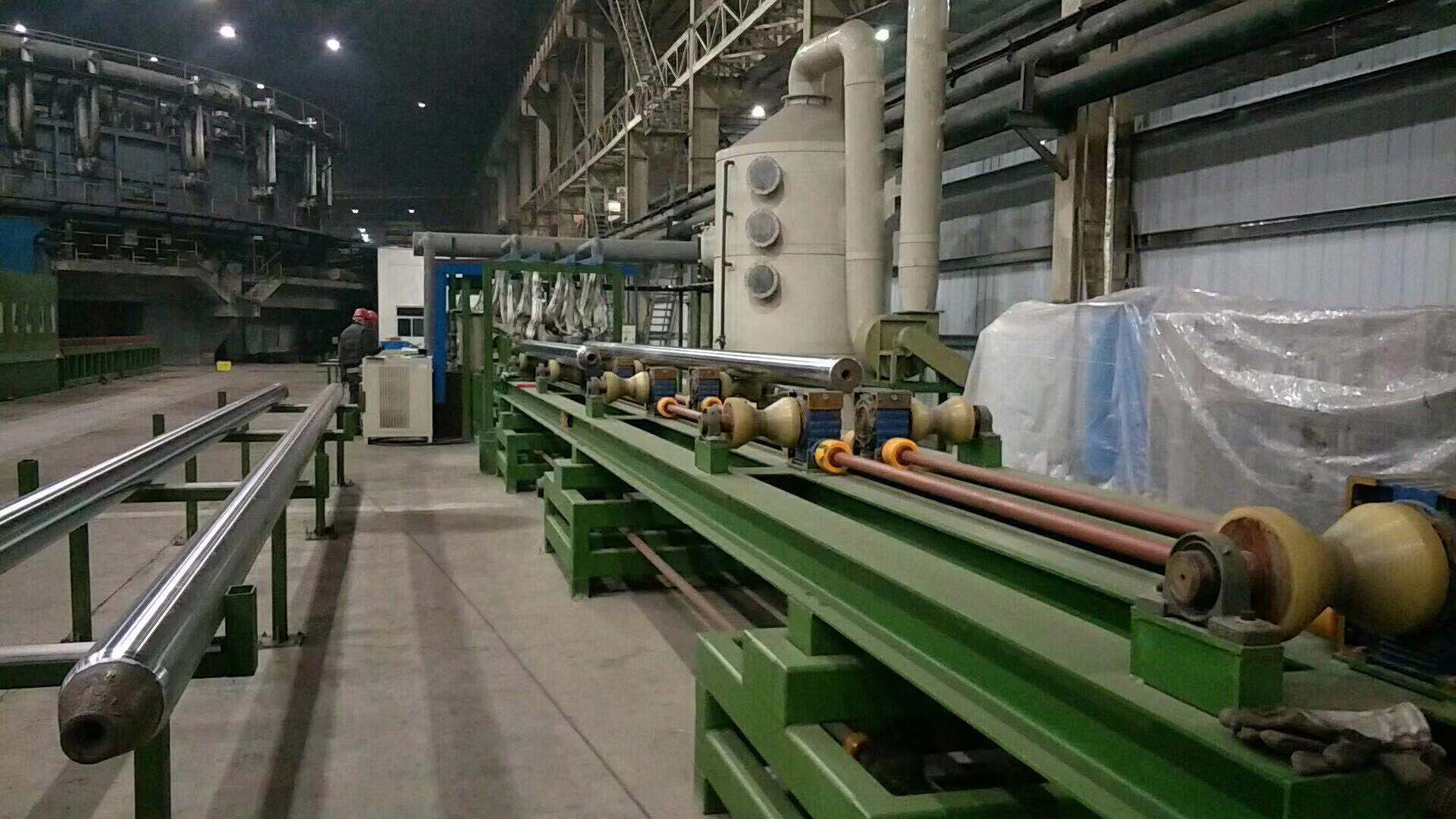

Electroplating Equipment

Product introduction: The device is used for coating the outer surface of the round bar material (slender shaft) with a multi-layer hard chromium plating...

Detailed Introduction

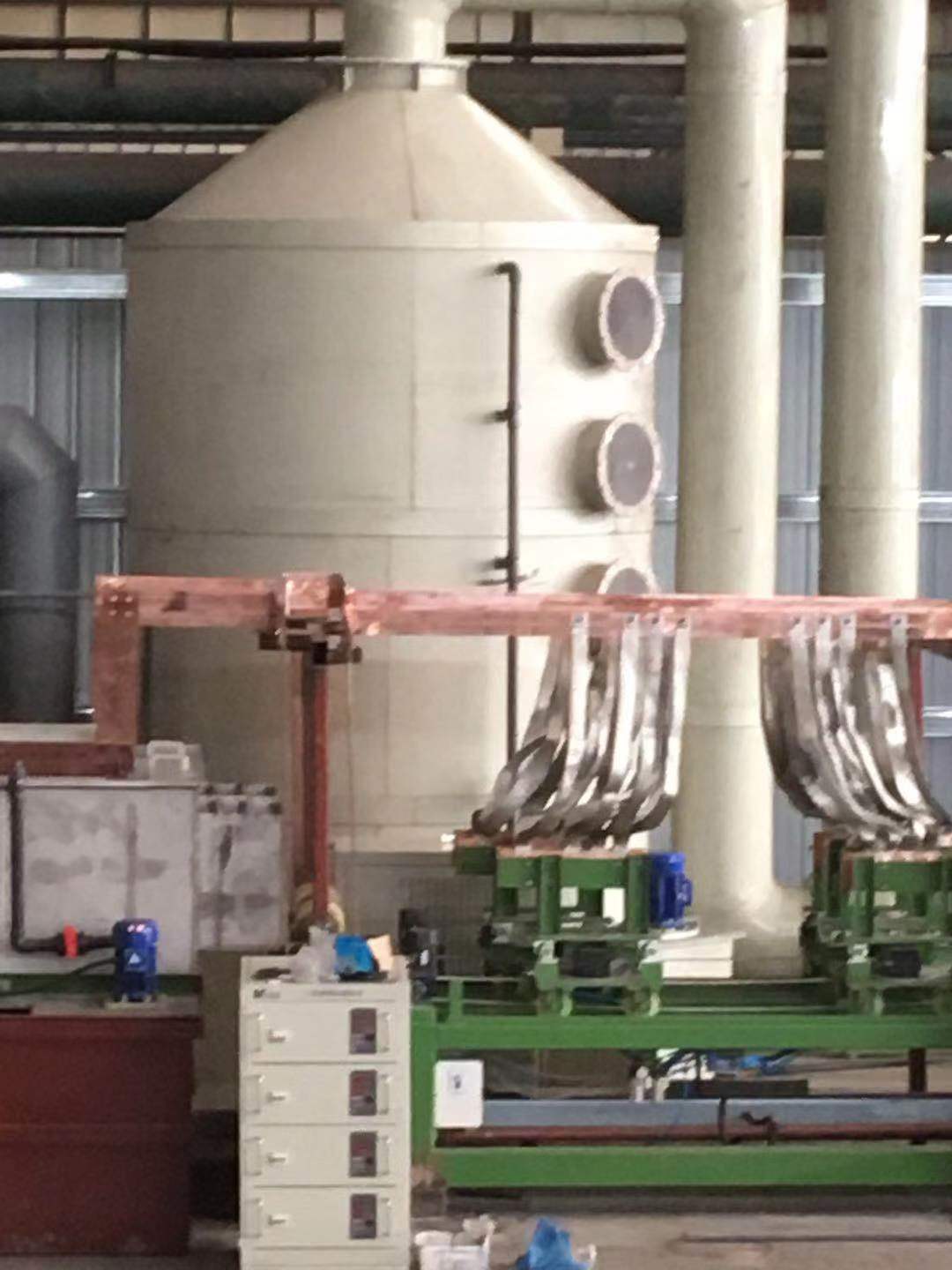

The device is used for coating the outer surface of the round bar material (slender shaft) with a multi-layer hard chromium plating by passing the bar through.There are automatic feeding device, plating pre-treatment device, automatic unloading device, chromatic acid mist recycling device in this system.

The system is energy saving and environmental protection to make products with the discharge of waste water chromium free. The washing water still flows into the master groove before and after the work-piece(processing target) is in the groove. Supplement the plating solution for its evaporation and decomposition decreasing. The plating tank and circulating tank ventilation are all channeled to chromium mist recycling and purification separation device. The detained chrome mist and washing water are guided to main tank to supply for the loss of plating evaporation, which saves energy and at the same time, protects the environment. Chromium mist recycling and purification tower ensure the quality of the purification effect, and at the same time achieve zero discharge of electroplating waste-water.

The anode plate distance between the work-pieces is relatively small. The work-piece passes through the imitation anode and moved in with even speed, which guarantees the evenness of plating coating both in circumference of the bar, or in the direction of the axis of the bar.

The system is energy saving and environmental protection to make products with the discharge of waste water chromium free. The washing water still flows into the master groove before and after the work-piece(processing target) is in the groove. Supplement the plating solution for its evaporation and decomposition decreasing. The plating tank and circulating tank ventilation are all channeled to chromium mist recycling and purification separation device. The detained chrome mist and washing water are guided to main tank to supply for the loss of plating evaporation, which saves energy and at the same time, protects the environment. Chromium mist recycling and purification tower ensure the quality of the purification effect, and at the same time achieve zero discharge of electroplating waste-water.

The anode plate distance between the work-pieces is relatively small. The work-piece passes through the imitation anode and moved in with even speed, which guarantees the evenness of plating coating both in circumference of the bar, or in the direction of the axis of the bar.

Technical Parameter

Work Requirements

Product Material: 45#,42CrMo .

Diameter Range: φ20mm~φ60mm;φ60mm~φ100mm;

Length Range: >4000mm

Surface Roughness: Ra0.2~0.8μm; Straightness: 0.1/1000

Plating Speed: 0 - 12m/h (according to customer's plating thickness requirements)

Maximum Feeding Speed: 35m/h

Finished products:

Coating Thickness: Coating Thickness 0-65um (one side)

Chromium Plating Appearance Requirements: Chrome plating layer must be continuous smooth, crystal delicate and mirror bright, with no non-plating part on the surface. The surface does not allow a pinhole, chrome bump, rough part, burr, peeling and other defects.

Chrome Layer Hardness: 60-65HRc. Chrome plated layer should be firmly coated, and does not shedding off in the test of reverse saw knife.

Product Material: 45#,42CrMo .

Diameter Range: φ20mm~φ60mm;φ60mm~φ100mm;

Length Range: >4000mm

Surface Roughness: Ra0.2~0.8μm; Straightness: 0.1/1000

Plating Speed: 0 - 12m/h (according to customer's plating thickness requirements)

Maximum Feeding Speed: 35m/h

Finished products:

Coating Thickness: Coating Thickness 0-65um (one side)

Chromium Plating Appearance Requirements: Chrome plating layer must be continuous smooth, crystal delicate and mirror bright, with no non-plating part on the surface. The surface does not allow a pinhole, chrome bump, rough part, burr, peeling and other defects.

Chrome Layer Hardness: 60-65HRc. Chrome plated layer should be firmly coated, and does not shedding off in the test of reverse saw knife.