- PRODUCTS

-

- CNC Metal Cutting Equipment

- Cylinder Processing Equipment

- Round Bar Peeling Machine

- Straightening Machine

- Chip Handling Equipment

- Polishing Machine

- Surface Grinder

- Electroplating Equipment

- Drawing Machine

- CNC Machining Center

- Center-less Grinding Machine

- Production Line

- Cylinder Processing

- Rolling Mill

- Free Forging Machine

- Chamfering&Facing Machine

- Heat Treatment Machine

- Vacuum pump

- Application

- Contacts Us

-

Mobile +8618663896299

-

Fax +86-535-6896668

-

E-mail: haige@haigechina.com

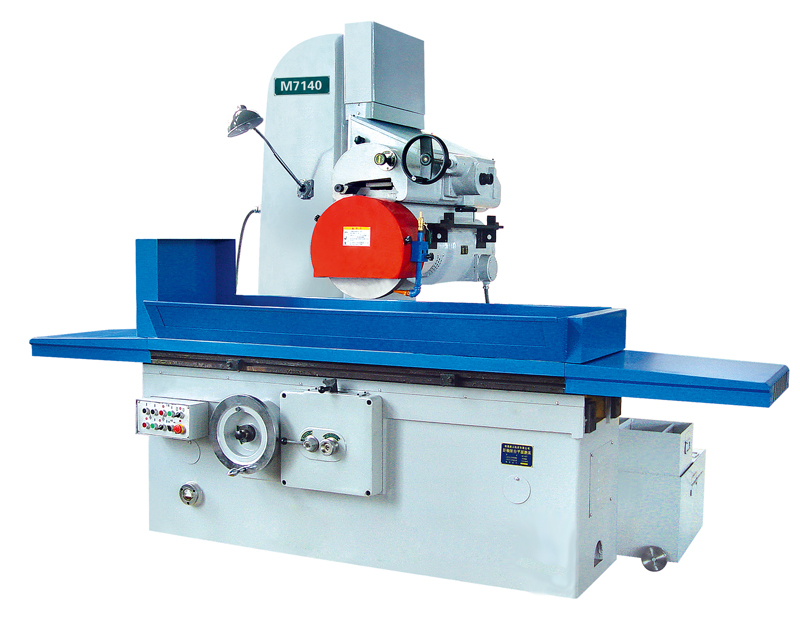

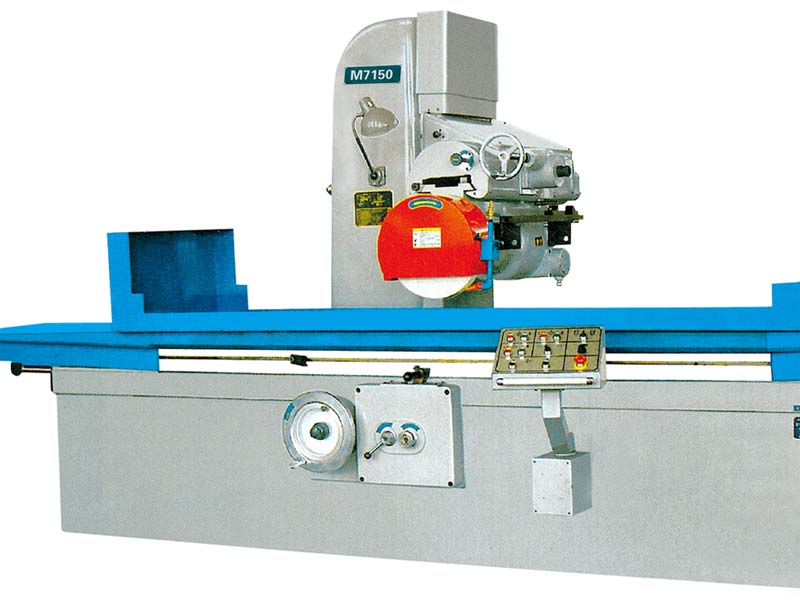

M7 series horizontal-spindle surface grinder

Detailed Introduction

What is surface grinder?

The surface grinding machine is a machine tool used to provide precision ground surfaces, either to a critical size or for the surface finish. It can process the work pieces with either the peripheral side or vertical plane of the grinding wheel. Usually There are three basic types of surface grinders: horizontal-spindle, vertical-spindle, single disc grinders and double-disc grinders. We only provide horizontal spindle type surface grinder.

How does a surface grinder work?

The work pieces are held in place by a magnetic chuck which directly fixed to the work table or held by other clamps. The work table makes longitudinal movement driven by hydraulic power and the grinding head can move transversely on the drag plate, hydraulically and or manually driven is available. Drag plate together with the grinding head can move vertically along the column, driven manually or mechanically.

The machine can grind work pieces made of steel, cast iron and non-ferrous metal etc.

What do we provide?

1. This series model can be equipped with one-axis digital display equipment (optional accessory).

2. Standard cooling, lubrication and lighting systems which will be provided with the machine.

3.The intermittent cross feed of wheel head per travel: 3-30mm (0.19-1.9”)/each time.

4.Power Supply:380-400v,3phase,50HZ.

5.Maximum Grinding Size(length x Width x Height):1000x400x290mm (39.4*15.7*11.4”).

6.8. A piece of grinding wheel free of charge.

7. The above pictures are for reference only, the machine will be subject to the actual equipment.

8.Please check the Tab Technical Parameter for detail specification.

Feel free to contact: haige@haigechina.com for further inquiry.

Technical Parameter

Model | M7132 | M7140 | M7150 | M7163 |

Working Table Size(mm) | 320*1000 | 400*1000 | 500*1250 | 630*1250 |

Max Grinding Size(W*L*H)(mm) | 320*1000*400 | 400*1000*525 | 500*1200*525 | 1250*630*500 |

Longitudinal Movement of Working Table(mm) | 200-1110 | 200-1110 | 200-1110 | 200-1350 |

Speed of Working Table(Stepless Speed)(m/min) | 3/25 | 3/25 | 3/25 | 3/25 |

T-Slot No. | 3 | 3 | 3 | 3 |

Width(mm) | 18 | 18 | 18 | 22 |

Distance from Grinding Wheel Center to Table Surface(mm) | 135-600 | 135-665 | 135-665 | 140-665 |

Max. Cross Travel of grinding head(mm) | 350 | 450 | 550 | 630 |

Max. Vertical travel of grinding head(mm) | 400 | 665 | 665 | 665 |

Handwheel scale value(per revolution)(mm) | 1 | 1 | 1 | 1 |

Grinding Wheel Size(OD*W*ID)(mm) | Ø350*40* Ø127 | Ø350*40* Ø127 | Ø400*50* Ø203 | Ø400*50* Ø203 |

Grinding Wheel Speed(r/min) | 1440 | 1440 | 1140 | 1140 |

Rapid Lifting motor(Power)(KW) | 0.37 | 0.37 | 0.37 | 0.37 |

Total Motor power(KW) | 11 | 11 | 12 | 14 |

Power of Grinding Head Motor(KW) | 7.5 | 7.5 | 7.5 | 11 |

Power of Hydraulic Pump(KW) | 3 | 3 | 5 | 5.5 |

Accuracy(mm) | 0.015*1000 | 0.015*1000 | 0.015*1000 | 0.015*1000 |

Roughness Ra(um) | Ra 0.63 | Ra 0.63 | Ra 0.63 | Ra 0.63 |

Magnet Chuck Size (W*L)(mm) | 320*1000 | 400*1000 | 500*1250 | 630*1250 |

Machine Dimension(L*W*H)(mm) | 2800*1750*2350 | 4500*2000*2350 | 3800*2700*2800 | 3800*2700*2800 |

Net Weight(Kg) | 4000 | 4500 | 5300 | 5600 |